Find Sewage Cast Iron Filter Press, Sewage Diaphragms Cast Iron Filter Press, Automatic Sewage Cast Iron Filter Press on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

New Products

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF,FCA,CPT |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 20 Days |

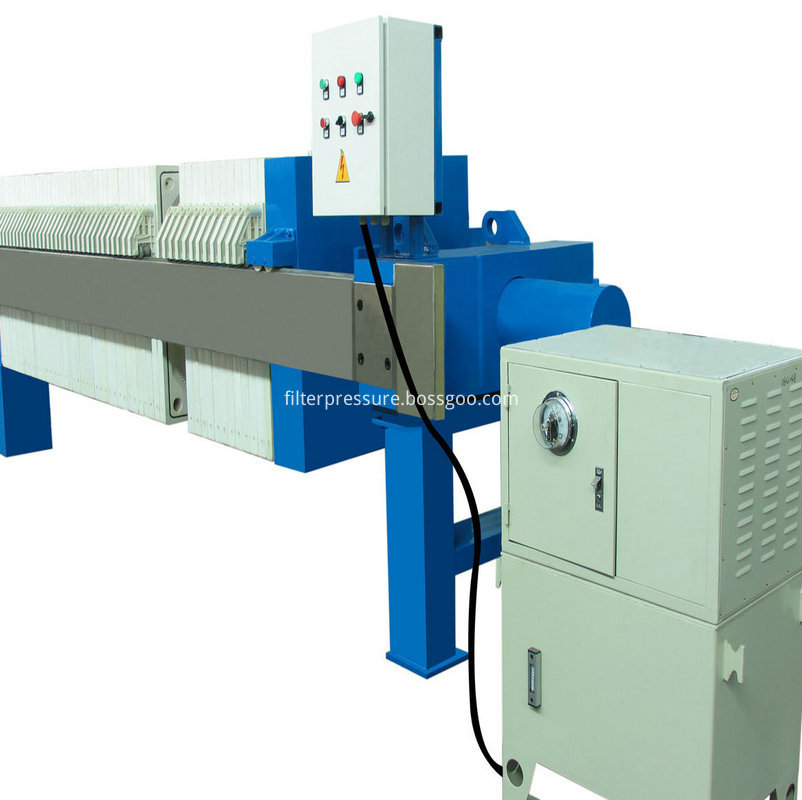

Model No.: XMAYZ-180

Sewage Cast Iron Filter Press Product Description

Sewage cast iron filter press is precisely casted by high quality cast iron or ductile cast iron. It specially apply to high temperature material. Plates have high strength, high filtration pressure bearing, and long service life. Filter press is widely used in coal-washing, metallurgy, chemical industry, ceramics, petroleum, oil, printing&dyeing, textiles, pharmacy, food&beverage, inorganic salt, paper making and various sewage treatment fields.

Sewage Cast Iron Filter Press Parameters

| Name | Sewage Cast Iron Filter Press |

| Filter Press Voltage | 380V |

| Filter Press Weight | 8600kgs |

| Plate Area | 180㎡ |

| Filter Press Warranty | 1 year |

Sewage Cast Iron Filter Press Photo

Cast Iron Filter Press Application

Solid-Liquid Separation for following:

Effluent Treatment Plants:

Textile, Paper, Leather, Jute, Sewages, Industrial & Municipal Waste Water.

Ceramics:

Clay, Porcelain, Fine Earth, Marble, and Granite.

Filter Press Metallurgy:

Electroplating & Electro Polishing, Steel Mill Waste, Nickel, Copper, Zinc, Silver Etc.,

Pharma Industries:

Antibiotic, Syrup, Intermediates and Bulk Drugs.

Chemical Industries:

Basic Chemicals, Organic & Inorganic, Resins, Starch, Enzymes, Pesticides, Activated Clay, Phosphoric Compounds, Marine Chemicals.

Dye Stuff:

Pigments, Dyes, Intermediates.

Filter Press Food Industries:

Vegetable Oils, Cane Juice, Food Colours Soups, Distilleries, Dairies, and Hotels.

Filter Press

Filter press is a popular dewatering and filtration equipment. The hydraulic filter press adopts hydraulic system to open and close the filter plates, and it can bear higher filtering pressure than other filter press closing types. For the hydraulic closing system, the most important element is the hydraulic valve, whose function is to control the oil-way. Generally, there are two oil ways (inlet oil-way and outlet oil-way). In addition, for the hydraulic filter press, the pressure gauge is necessary, because it can control the pressure within a range to realize pressure maintenance. Automatic membrane filter press uses PLC programming, which can realize program-controlled.

Contact Us

Product Categories : Sewage Filter Press > Sewage Cast Iron Filter Press